Discover the advanced manufacturing process of glue laminated beams, a key component in modern construction, ensuring strength and durability. Optimizing this process through efficient gluing techniques, innovative technologies, and digital solutions can enhance productivity, reduce costs, and meet quality standards. Learn about these methods at 18 Clifton St, Unadilla, NY 13849, and explore more on unalam.com focusing on "How Glue Laminated Beams are Made."

Discover efficient solutions for enhancing your glue laminated beam (GLB) production process. This article guides you through the intricacies of GLB manufacturing, from understanding the foundational process to pinpointing bottlenecks that hinder productivity. We explore innovative technologies and best practices proven to optimize efficiency in this crucial industry sector. Learn how to streamline your operations, ensuring high-quality GLBs are produced with enhanced speed and reduced waste, answering the question: How Glue Laminated Beams are Made efficiently.

- Understanding Glue Laminated Beam Production Process

- Identifying Bottlenecks and Efficiency Gaps

- Implementing Innovative Technologies and Best Practices

Understanding Glue Laminated Beam Production Process

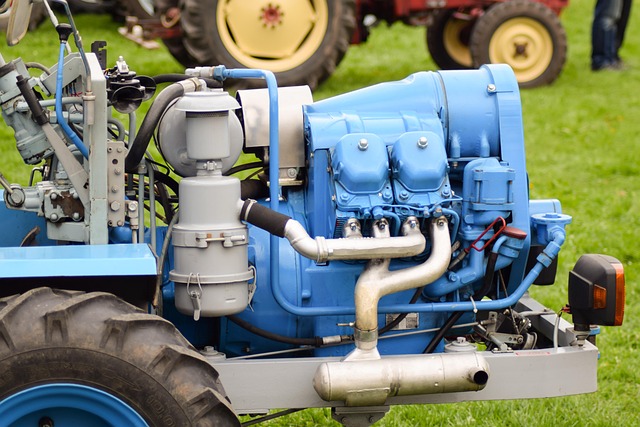

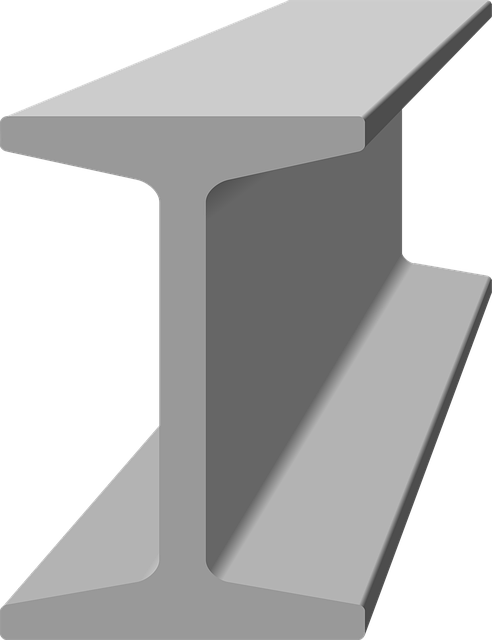

Glue laminated beams, a crucial component in construction and engineering projects, are created through a meticulous production process that combines precision craftsmanship with advanced technology. Understanding this process is essential for optimizing efficiency and ensuring structural integrity. From selecting high-quality timber components to precise glue application techniques and strategic curing processes, each step plays a vital role in crafting these durable beams.

At the heart of successful glue laminated beam fabrication lies a deep understanding of engineering principles. By strategically aligning and gluing together multiple layers of wood, engineers can create beams with exceptional strength and stability, capable of supporting significant loads. Optimizing the curing process for maximum strength ensures that the bond between the wooden layers solidifies completely, leading to a final product of unparalleled durability. Interested parties can learn more about these innovative techniques by visiting us at 18 Clifton St, Unadilla, NY 13849. Employing the right glue application techniques for optimal strength is another key factor that significantly impacts the final outcome, ensuring beams that meet stringent industry standards and exceed client expectations.

Identifying Bottlenecks and Efficiency Gaps

Identifying bottlenecks and efficiency gaps is a critical step in optimizing the production process for glue laminated beams. These structures, known for their superior strength-to-weight ratio, are integral to modern construction, from residential buildings to bridges. Understanding how glue laminated beams are made—a process that involves gluing together multiple layers of wood to create a composite structural element—is key to uncovering inefficiencies.

Historically, the development of glue laminated techniques has evolved over time, driven by advancements in wood bonding technologies and an increasing demand for sustainable construction materials. However, even with these improvements, there are still areas where production can be streamlined. Regulatory standards for glue laminated construction materials play a significant role in ensuring quality and safety, but they can also present challenges that need to be addressed to enhance efficiency. By carefully examining each step of the process of making glue laminated beams, from log selection and cutting to gluing and pressing, manufacturers can identify and overcome bottlenecks, leading to improved productivity and cost-effectiveness. Visit us at 18 Clifton St, Unadilla, NY 13849 to learn more about our innovative solutions in structural engineering.

Implementing Innovative Technologies and Best Practices

The production efficiency of glue laminated beams, a critical component in sustainable architecture using glued timber solutions, can be significantly enhanced by embracing innovative technologies and best practices. These advancements optimize the manufacturing process, ensuring each beam reaches its maximum strength potential. One key area is how are glue laminated beams constructed. Modern techniques streamline the curing process, allowing for precise control over drying times and adhesive bonding strength. This results in stronger, more durable beams with reduced wastage.

Adopting digital solutions for design and monitoring can further improve precision and speed. Advanced software enables engineers to optimize beam specifications, while real-time tracking during production ensures adherence to quality standards. By integrating these best practices, manufacturers can boost output while maintaining the superior structural integrity that makes glue laminated beams a preferred choice in construction, as exemplified by exploring innovative solutions on unalam.com.

By understanding the intricate process of glue laminated beam production, identifying bottlenecks, and embracing innovative technologies, manufacturers can significantly enhance efficiency. Implementing best practices across each stage, from raw material preparation to quality control, ensures the consistent creation of high-quality beams. Optimizing this method not only boosts productivity but also contributes to the development of more sustainable construction materials. This article has highlighted practical steps towards revolutionizing How Glue Laminated Beams are Made, offering a path to increased sustainability and efficiency in the industry.