Learn how glue laminated beams (GLBs) are crafted using high-quality timber and advanced synthetic resins adhesives. Modern techniques involve precise cutting, lamination, and curing control for superior structural integrity and reduced environmental impact. Discover GLB's benefits: strong, durable, eco-friendly, supporting larger interior spaces without support. Explore industry trends towards innovative, sustainable beam manufacturing methods for informed project decisions.

“Explore the evolution of construction with a focus on modern innovations in glue laminated beam technology. This comprehensive review delves into the intricate process of creating these structural wonders, known for their strength and versatility. From understanding the glue lamination process to exploring advanced manufacturing techniques, we uncover how these beams are made using cutting-edge materials and adhesives. Additionally, we examine the environmental impact and future trends shaping this sustainable construction method.”

- Understanding the Glue Lamination Process

- Materials and Adhesives Used in Modern Beams

- Advantages of Glue Laminated Beam Construction

- Advanced Manufacturing Techniques for Beams

- Sustainability and Future Trends in Beam Technology

Understanding the Glue Lamination Process

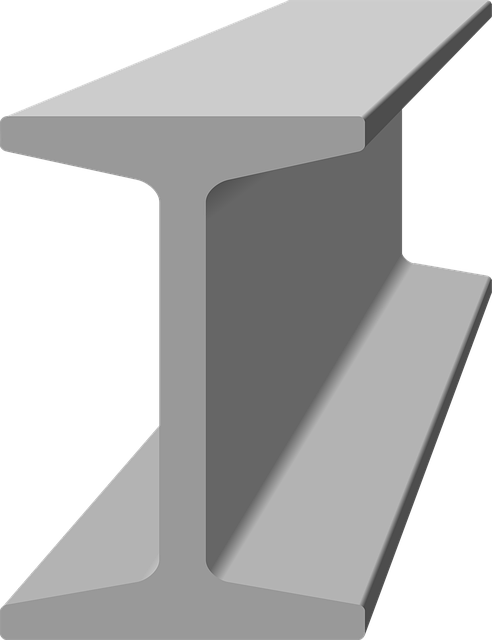

The glue lamination process involves fusing multiple layers of wood together using a strong adhesive, creating sturdy glue laminated beams. This modern innovation began with historical development of glue laminated techniques that have evolved over time. By carefully selecting and arranging wood veneers, a core structure is formed, which is then bonded with a high-performance glue to create a single, seamless beam. This technique significantly enhances the structural integrity and dimensional stability of timber, making it a viable alternative to steel for structural support in various applications.

Choosing the right glue is crucial in the lamination process. Different adhesives have varying bond strengths, resistance to moisture, and flexibility, each suited for specific wood types and project requirements. Manufacturers often provide guidelines on the best glue for their laminated beams, ensuring optimal performance and longevity. For instance, exploring the options available and consulting with experts can help determine the ideal adhesive, enhancing the structural efficiency of glue laminated beams. Visit us at 18 Clifton St, Unadilla, NY 13849 anytime to learn more about these innovative building solutions.

Materials and Adhesives Used in Modern Beams

Modern innovations in glue laminated beam technology have significantly advanced the way we construct buildings, focusing on both strength and sustainability. The core of these beams lies in the materials and adhesives used, which play a pivotal role in their structural integrity and environmental impact. High-quality timber from managed forests is commonly employed, ensuring a renewable resource that forms the backbone of these innovative construction methods.

Advanced adhesives, such as synthetic resins, have revolutionized how Glue Laminated Beams (GLBs) are created. These adhesives not only strengthen the bond between layers of wood but also contribute to the overall sustainability considerations in glued timber production. By adhering to best practices for field assembly of GLBs, including precise cutting and efficient bonding techniques, builders can create robust structures that meet modern engineering standards. For those interested in exploring these innovative construction methods with glue laminated beams, give us a call at (607) 369-9341 to learn more about the best practices and how they can be implemented on your next project.

Advantages of Glue Laminated Beam Construction

Glue laminated beam technology offers numerous advantages over traditional construction methods, making it an increasingly popular choice for modern architecture and engineering projects. The process involves carefully layering and binding multiple pieces of wood with high-strength glue, resulting in structural beams that are remarkably strong and durable. This innovative technique not only enhances the structural integrity of buildings but also contributes to sustainability efforts.

One of the key benefits is its ability to create large spans without intermediate support, allowing for more open and flexible interior spaces. Additionally, the lamination process ensures superior dimensional stability, minimizing warping or cracking over time. Moreover, glue laminated wood products have a lower environmental impact compared to alternative materials, as they are renewable and can be sourced sustainably. To learn more about this groundbreaking technology, visit unalam.com and explore the engineering principles and environmental benefits that make glue laminated beams a game-changer in construction.

Advanced Manufacturing Techniques for Beams

Modern advancements in manufacturing have significantly revolutionized the way glue laminated beams are produced, enhancing both their strength and durability. The process begins with precise cutting and shaping of individual timber elements to create layers that will form the beam. These layers are then carefully arranged, ensuring even spacing and alignment for optimal structural integrity.

What sets modern techniques apart is the meticulous control over curing time and temperature during lamination. This careful manipulation ensures the adhesive properties of the glue are optimized, leading to superior bonding strength between the layers. As a result, these advanced manufacturing methods not only expedite production but also contribute to the sustainability benefits of glue laminated construction, making it an eco-friendly choice for building materials. For more information on how glue laminated beams are made and their remarkable properties, give us a call at (607) 369-9341.

Sustainability and Future Trends in Beam Technology

Glue laminated beams, known for their exceptional strength and structural integrity, have long been a cornerstone in modern construction. The process begins with carefully selected wood veneers that are pressure-adhered together using advanced wood adhesive bonding technology. This innovative technique involves optimizing beam strength through precise lamination techniques, ensuring each layer enhances overall structural performance without adding excessive weight. As the industry evolves, sustainability emerges as a key focus, driving advancements in how glue laminated beams are made. By embracing eco-friendly materials and efficient manufacturing processes, manufacturers aim to reduce their environmental footprint while meeting stringent regulatory standards for glue laminated construction materials.

Looking ahead, future trends in beam technology promise even greater efficiency and durability. Research into new adhesives and lamination methods could lead to lighter, stronger, and more sustainable beams. Staying attuned to these developments is crucial for professionals in the field. For those eager to explore further, give us a call at (607) 369-9341 to discuss the latest advancements and how they can be leveraged in your next project.

Modern innovations in glue laminated beam technology have revolutionized construction, offering enhanced structural integrity, sustainability, and efficiency. By understanding the intricate glue lamination process, utilizing advanced manufacturing techniques, and exploring eco-friendly materials, we can create stronger and more durable beams. These improvements not only benefit the construction industry but also contribute to a greener future. The ongoing evolution of glue laminated beam construction promises exciting prospects for sustainable and innovative building practices.