Glue laminated beams (GLBs) are engineered wood products with superior structural integrity, crafted through a meticulous process from premium timber selection to specialized gluing and high-pressure pressing. Modern manufacturing techniques prioritize efficiency, sustainability, and precision, revolutionizing beam production for quicker turnarounds while maintaining strength and quality. Advanced adhesives, streamlined processes, and waste reduction at facilities like 18 Clifton St, Unadilla, NY, ensure GLBs' reliability in construction projects, with pricing reflecting their intricate manufacturing. Learn more about the crafting process and pricing dynamics at unalam.com.

“Discover the secrets behind fast turnaround glue laminated beams—a game-changer in construction. This comprehensive guide delves into the intricate process of producing these structural marvels, ‘how glue laminated beams are made’. From understanding raw material choices to navigating manufacturing steps, we explore key factors influencing production time. Learn about pricing structures and techniques that enable quick turnaround, offering a unique perspective on this efficient and cost-effective solution for construction projects.”

- Understanding Glue Laminated Beam Production

- Key Factors Influencing Turnaround Time

- Raw Materials and Their Costs

- Manufacturing Processes: Step-by-Step

- Fast Turnaround: Techniques and Trade-Offs

- Pricing Structure for Quick Beams

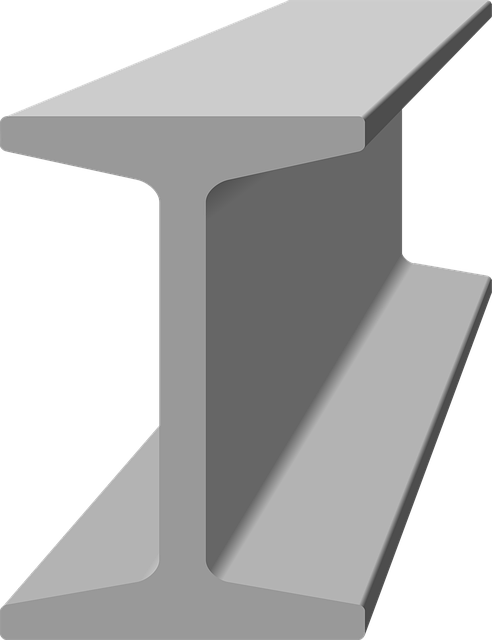

Understanding Glue Laminated Beam Production

Glue laminated beams are engineered wood products created through a meticulous manufacturing process. The journey begins with selecting high-quality, premium lumber. These logs undergo careful grading and cutting to ensure consistency in size and strength. Next, the boards are carefully arranged and aligned, often in a specific pattern, to maximize structural integrity.

A crucial step is the application of wood adhesives, which bind the layers together. Understanding health and safety considerations in glue application is paramount for both workers and the environment. Advances in wood adhesive bonding technology have led to stronger, more efficient glues that enhance the overall quality of the beams. Once glued, the laminated logs are pressed under high pressure and temperature, fusing the layers into a single, robust beam. After curing, these beams are precision-cut to desired dimensions and ready for use in construction projects. Visit us at 18 Clifton St, Unadilla, NY 13849 anytime to see this process firsthand. Choosing the right glue for your specific application is also essential, as different adhesives offer varying levels of strength, durability, and workability.

Key Factors Influencing Turnaround Time

The speed at which glue-laminated beams (GLBs) can be produced for a fast turnaround is significantly influenced by several key factors. Firstly, the complexity of the design plays a crucial role; more intricate beam shapes or custom requirements generally demand more time for manufacturing. Secondly, the scale of the order affects turnaround times; larger batches often benefit from economies of scale in production processes. Additionally, the availability and accessibility of raw materials can impact timelines, as delays in obtaining high-quality timber can slow down the lamination process.

Understanding how glue laminated beams are made is essential for appreciating the factors that contribute to their fast turnaround. The lamination process involves bonding multiple layers of timber with glues specifically designed for structural applications. Best practices for gluing, including precise temperature and pressure control, ensure the longevity and performance of glued timber structures. Visiting unalam.com can offer further insights into these manufacturing processes and best practices, highlighting the expertise behind fast turnaround times while maintaining superior performance and longevity of GLBs.

Raw Materials and Their Costs

The production of glue laminated beams begins with raw materials—a crucial aspect that significantly influences the final cost. High-quality timber, typically sourced from sustainable forests, is the primary component. This timber undergoes meticulous selection and grading to ensure consistency in strength and quality. The choice of species varies based on project requirements and availability, but common options include spruce, pine, fir (SPF), and hemlock.

Beyond wood, the glue laminated beam process demands specialized adhesives, which contribute to the overall price estimate. Modern production methods favor efficient, cost-effective glues that enhance structural integrity while maintaining environmental sustainability. Efficient production techniques, such as those employed at 18 Clifton St, Unadilla, NY 13849, aim to streamline manufacturing, reducing labor and material waste. Compare glued vs. unglued lumber beams; the former offers superior strength-to-weight ratios, making it ideal for mass housing projects. Case studies of successful glue laminated projects demonstrate its versatility in construction, further justifying the investment in this efficient production method.

Manufacturing Processes: Step-by-Step

The manufacturing process of glue laminated beams involves several precise steps to ensure structural integrity and quality. It begins with selecting high-quality timber, carefully grading them based on strength and appearance. The logs are then debarked, sawn into planks, and dried to achieve optimal moisture content. Next, these planks undergo a rigorous process of gluing and pressing, where multiple layers of wood are bonded together using specialized adhesives. This step requires precise temperature and pressure control for optimal glue performance.

After the laminating process, the beams are cut to specified dimensions and further treated to enhance their mechanical properties. This includes sanding for smoothness and applying protective coatings or finishes. The final stage involves thorough quality checks to verify the beams’ dimensional stability and structural capabilities, ensuring they meet industry standards and best practices for gluing in challenging environments. Visit us at 18 Clifton St, Unadilla, NY 13849 anytime to learn more about our state-of-the-art manufacturing processes and the mechanical properties of different glues used for beams.

Fast Turnaround: Techniques and Trade-Offs

Fast turnaround glue laminated beams involve advanced techniques and thoughtful consideration of trade-offs to ensure quality and efficiency. The process begins with selecting appropriate adhesive systems, crucial for achieving robust structural integrity in a fraction of the time compared to traditional methods. The historical development of glue laminated techniques has evolved significantly, driven by the demand for faster, more efficient construction. Today, best practices for field assembly of glue laminated beams, like those at 18 Clifton St, Unadilla, NY 13849, prioritize precision and safety while leveraging these advancements.

Adhesive systems play a pivotal role in fast turnaround, with modern formulations offering superior bonding strength, reduced curing times, and improved workability. These innovations allow for more precise laminations, reducing waste and streamlining the fabrication process. By carefully balancing speed and quality, construction professionals can deliver high-performance structural elements while meeting tight project deadlines.

Pricing Structure for Quick Beams

The pricing structure for fast turnaround glue laminated beams is intricately tied to several factors that influence their production and assembly. These beams, known for their strength and versatility, are primarily crafted through a meticulous manufacturing process. How Glue Laminated Beams are Made involves layering and gluing together multiple pieces of wood to create a single, robust component. Each step, from material selection to drying and quality control, contributes to the final cost.

Modern design possibilities with glue laminated frames offer architects and engineers creative freedom, but they also require precise execution. Reducing waste in glue laminated beam fabrication is a significant focus for manufacturers, as it not only minimizes environmental impact but also optimizes production efficiency. Quality control measures in glue laminated manufacturing are crucial to ensure structural integrity and consistency across batches, further impacting the overall pricing structure. To explore these aspects and more, visit us at unalam.com.

Understanding the intricate process of producing glue laminated beams, from raw material selection to precise manufacturing techniques, is key to appreciating their quality and value. By optimizing turnaround times through advanced methods and skilled labor, manufacturers can offer competitive pricing for these structural components, making them a viable choice for projects demanding both speed and strength. Knowing the factors that influence cost, including material choices and production complexities, allows clients to make informed decisions when specifying fast turnaround glue laminated beams for their construction needs.