"Learn about the innovative and sustainable construction solution of How Glue Laminated Beams are Made. From selecting premium timber to advanced lamination technology, each step ensures strength and precision. These beams offer superior structural integrity, reduced waste, and aesthetic versatility, making them a game-changer in both residential and commercial construction. Visit 18 Clifton St, Unadilla, NY 13849 for more information."

“Discover the strength and versatility of glue laminated beams—a revolutionary wood product. This comprehensive guide delves into the intricate process of creating these structural wonders, from selecting high-quality raw materials to advanced lamination techniques. We explore cost factors influencing pricing, guiding you in identifying reliable local suppliers. Learn about quality assurance measures ensuring structural integrity and the diverse applications of glue laminated beams, making them an essential building block for modern construction.”

- Understanding Glue Laminated Beams: A Comprehensive Guide

- The Process: From Raw Materials to Final Product

- Cost Factors: Unraveling the Pricing Structure

- Identifying Reliable Suppliers in Your Area

- Quality Assurance: Ensuring Structural Integrity

- Applications and Benefits of Glue Laminated Beams

Understanding Glue Laminated Beams: A Comprehensive Guide

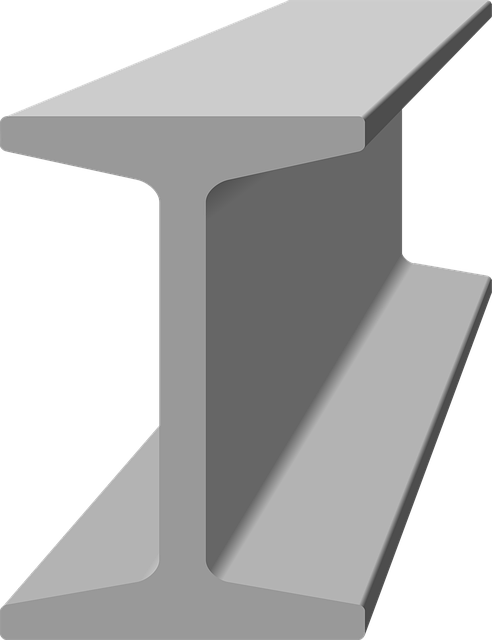

Glue laminated beams are an innovative and sustainable solution in construction, offering both strength and versatility. The process begins with selecting high-quality timber from responsibly managed forests. Each log is carefully evaluated to ensure it meets strict criteria for straightness and quality. Once chosen, the logs are debarked and cut into specific lengths, forming the individual lamellas or layers that will compose the beam.

The heart of the process lies in the technology behind glue laminated timber. These lamellas are glued together using advanced bonding agents, creating a single, unified beam. This method not only enhances the structural integrity but also allows for larger and lighter construction components. The sustainability benefits of glue laminated construction are significant, as it reduces waste compared to traditional solid wood beams and can be made from recycled or certified sustainable timber. Best practices for gluing in challenging environments, such as high humidity or extreme temperatures, ensure robust bonds and prolonged beam longevity. For all your glue laminated beam needs, visit us at 18 Clifton St, Unadilla, NY 13849 anytime.

The Process: From Raw Materials to Final Product

The journey of creating glue laminated beams begins with selecting high-quality raw materials, primarily timber. This timber is carefully chosen for its strength and durability, ensuring it meets specific grade standards. Once sourced, the logs undergo a series of processes to transform them into boards. These boards are then cut to precise dimensions, forming the individual lamina or layers that make up the beam.

The heart of the process lies in the lamination stage where these thin wood layers are bonded together using a specialized adhesive, typically a strong and durable glue. This adhesive not only binds the layers but also enhances the structural integrity of the final product, providing remarkable strength and stability. The choice of glue is critical; professionals must select a type that offers superior bonding strength and contributes to the insulating properties of glue laminated wood structures. After lamination, the beams undergo rigorous quality checks to ensure they meet regulatory standards for glue laminated construction materials. This meticulous process guarantees not only exceptional structural performance but also safety and reliability in various construction projects. To learn more about this fascinating manufacturing process, visit unalam.com.

Cost Factors: Unraveling the Pricing Structure

The cost of glue laminated beams can vary greatly depending on several factors. Understanding how these beams are made is essential to unraveling their pricing structure. Glue laminating involves bonding multiple layers of wood together with adhesive, creating a strong and durable product. This process requires careful selection of wood species, precise application of adhesives, and controlled pressing to ensure optimal performance.

While the initial production costs can be relatively high, one of the primary advantages lies in its efficiency and environmental benefits. The method reduces waste compared to traditional solid lumber construction, as it utilizes smaller pieces of wood, minimizing the need for vast resources. Moreover, the aesthetic advantages of glue lamination in architecture cannot be overlooked; its versatility allows for intricate designs and unique structural elements that can enhance a building’s visual appeal. Visit us at 18 Clifton St, Unadilla, NY 13849 to experience these benefits firsthand. The environmental impact of glue laminated wood products is also lower, as it requires fewer trees to produce the same strength and stability as solid lumber.

Identifying Reliable Suppliers in Your Area

Identifying Reliable Suppliers in Your Area

When looking for the cheapest glue laminated beam suppliers near you, it’s crucial to prioritize quality and reliability. These beams, crafted through an intricate process known as how glue laminated beams are made, involve combining multiple layers of timber with powerful adhesive systems used in beam fabrication. This method not only enhances the structural integrity but also ensures longevity and performance of glued timber structures. To find the best providers in your area, start by researching local lumber yards and engineering supply stores. Online platforms can also be useful for comparing prices and reading customer reviews, helping you narrow down options to those with consistent quality and efficient production methods for mass housing with glue.

Remember that the right supplier should not only offer competitive pricing but also possess deep industry knowledge and commitment to sustainability, ensuring your project meets both cost and performance expectations. Don’t hesitate to give us a call at (607) 369-9341 for personalized guidance tailored to your specific needs.

Quality Assurance: Ensuring Structural Integrity

Glue laminated beams are crafted through a meticulous process that prioritizes quality assurance for structural integrity. Manufacturers start by selecting high-quality timber, free from defects or rot, ensuring each beam meets stringent standards. This initial step is crucial as it sets the foundation for the beam’s overall strength and durability. The timbers are then glued together in layers, a technique known for enhancing both the strength and longevity of the final product. Innovations in adhesive technology for construction play a pivotal role here, allowing for stronger bonds that can withstand considerable stress.

After lamination, the beams undergo rigorous testing to verify their structural integrity and performance. This includes assessments for load-bearing capacity, flexibility, and resistance to environmental factors. By adhering to these strict protocols, suppliers ensure that the glue laminated beams they offer maintain consistent quality. For those seeking reliable options, visiting us at 18 Clifton St, Unadilla, NY 13849 anytime can provide firsthand insights into the craftsmanship and attention to detail that go into creating glued timber structures known for their strength and durability.

Applications and Benefits of Glue Laminated Beams

Glue laminated beams are engineered wood products that have revolutionized the construction industry for their exceptional strength and versatility. These beams are created through a meticulous process, known as How Glue Laminated Beams are Made, where multiple layers of wood veneers are bonded together with strong adhesives under high pressure. This method optimizes the curing process, ensuring maximum strength and durability. Each layer contributes to the beam’s overall structural integrity, making them ideal for various applications.

From residential buildings to commercial structures, glue laminated beams offer numerous advantages. They provide cost-effective solutions without compromising on quality and performance. The fire safety features of glued timber beams make them a preferred choice for projects where flame resistance is essential. Whether it’s supporting roof structures or creating load-bearing walls, these beams can be customized to meet specific project requirements. Visit us at 18 Clifton St, Unadilla, NY 13849 to explore our range and discover how glue laminated beams can transform your construction endeavors.

Glue laminated beams, known for their exceptional structural integrity and cost-effectiveness, are a game-changer in construction. Understanding their manufacture, from raw materials to final product, is key to recognizing their benefits. By identifying reliable local suppliers through thorough research and quality assurance checks, you can ensure access to these versatile building elements at competitive prices. Whether for residential or commercial projects, glue laminated beams offer a strong, sustainable solution, making them an essential consideration for modern builders. To find the cheapest glue laminated beam suppliers near you and unlock these advantages, take a dive into local options today.