Beam gluing fabricates strong structural elements for green building using multiple wood layers. Proper strategies reduce waste: optimized cutting patterns, alternative uses for by-products, efficient adhesive application techniques, and advanced pressing technologies. Regulatory standards emphasize minimizing waste in glue laminated construction materials. Efficient glue application and precise cutting techniques significantly reduce waste during beam gluing, an essential step in manufacturing high-quality glue laminated beams. Automation streamlines the process, enhances efficiency, and reduces waste.

Reducing waste during beam gluing is essential for both cost savings and environmental sustainability. This article explores comprehensive solutions to minimize debris generated in the production of glue-laminated beams, delving into critical aspects like understanding the gluing processes, pinpointing waste hotspots, and implementing efficient practices. We also examine eco-friendly glues, automated systems, and optimized material handling techniques, providing insights on how glue laminated beams are made with less waste.

- Understanding Beam Gluing Processes

- Identifying Common Waste Generation Points

- Implementing Efficient Glue Application Techniques

- Optimizing Material Cutoffs and Trimmings

- Exploring Eco-Friendly Glue Options

- Adopting Automated Systems for Reduced Waste

Understanding Beam Gluing Processes

The process of beam gluing, or glue laminated beam fabrication, involves joining multiple layers of wood to create structural elements used in construction. This method is renowned for its strength and efficiency, especially in green building strategies incorporating glued wood. By bonding together various boards, a single glue laminated beam can achieve dimensions that would be impractical to assemble from individual pieces. However, while this manufacturing process offers significant advantages, it’s not without challenges when it comes to waste management. Understanding how glue laminated beams are made is the first step towards identifying areas for improvement in reducing waste during production.

The core of the beam gluing process involves applying adhesive to wood boards and pressing them together under high pressure and temperature. This creates a strong bond between the layers, forming a single structural element. However, this precision fabrication can lead to significant scrap material generation if not managed properly. Waste reduction strategies should focus on optimizing cutting patterns, utilizing by-products for alternative uses, and implementing efficient adhesive application techniques. Give us a call at (607) 369-9341 to explore tailored solutions for your construction projects, ensuring both quality beams and a reduced environmental footprint.

Identifying Common Waste Generation Points

Identifying Common Waste Generation Points in Glue Laminated Beam Production

The process of creating glue-laminated beams, also known as how glue laminated beams are made, involves several stages that can lead to waste generation if not managed properly. Understanding these points is crucial for minimizing environmental impact and adopting sustainable practices within the wood products industry, particularly in the realm of architectural solutions. The initial step involves selecting and preparing the timber, where offcuts and residuals often arise due to variations in tree growth and sawing techniques. These initial waste streams can be mitigated through precise cutting strategies and utilizing by-products for alternative uses.

Subsequently, during the laminating phase, where multiple layers of wood are bonded together with glue, inefficiencies can result in surplus glue and material wastage. Advanced pressing technologies and meticulous glue application methods can significantly reduce this aspect. Moreover, regulatory standards for glue laminated construction materials, such as those found at 18 Clifton St, Unadilla, NY 13849, emphasize the importance of minimizing waste, ensuring products meet high-quality and environmental sustainability criteria. In light of these considerations, embracing sustainable architecture using glued timber solutions can substantially decrease the environmental impact of glue laminated wood products.

Implementing Efficient Glue Application Techniques

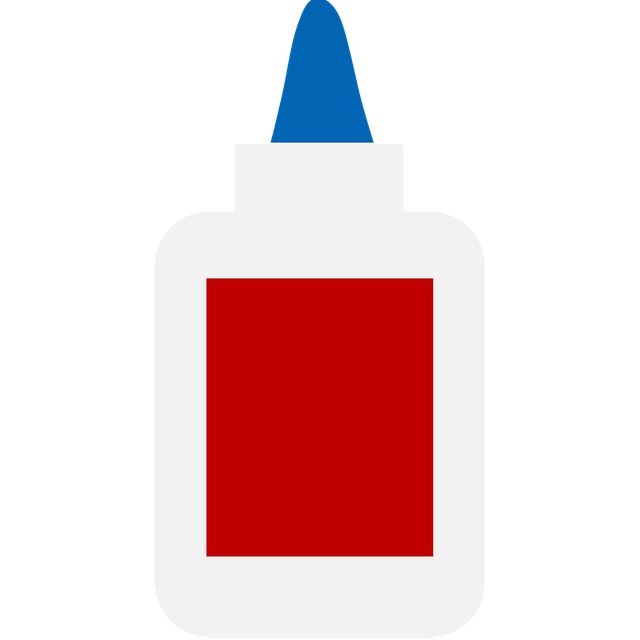

Implementing efficient glue application techniques is a key strategy in reducing waste during beam gluing, an integral process in manufacturing high-quality glue laminated beams. Understanding how glue laminated beams are made involves recognizing that precise and controlled glue application ensures optimal bonding between layers while minimizing material waste. Best practices for gluing in challenging environments involve employing advanced tools and techniques to handle various beam configurations and material types.

Quality control measures in glue laminated manufacturing play a crucial role in ensuring consistency and reducing scrap. Regular inspections, automated systems, and rigorous testing procedures help maintain high standards throughout the production process. Case studies of successful glue laminated projects demonstrate how these strategies can be implemented effectively to achieve remarkable results while minimizing waste. For tailored solutions and expert guidance, give us a call at (607) 369-9341.

Optimizing Material Cutoffs and Trimmings

Optimizing material cutoffs and trimmings is a critical aspect of reducing waste during beam gluing, a process integral to modern construction using glue laminated beams. By implementing precise cutting techniques and utilizing every feasible piece of material, manufacturers can significantly minimize residual waste. Innovations in adhesive technology for construction play a crucial role here; advanced glues allow for more efficient bonding, ensuring that even smaller fragments of wood can be repurposed, leading to less overall waste.

Quality control measures in glue laminated manufacturing are essential to achieving this optimization. Regular inspections and strict adherence to best practices for field assembly of glue laminated beams ensure that cuts are accurate and tailored to the beam’s specific requirements. This meticulous approach not only reduces material wastage but also enhances the structural integrity of the final product, ensuring longevity and quality. Visiting us at 18 Clifton St, Unadilla, NY 13849 anytime can provide further insights into these best practices and their impact on sustainable construction.

Exploring Eco-Friendly Glue Options

The process of gluing beams, known as glue laminating, plays a significant role in modern construction methods, offering durable and strong structural elements. When it comes to reducing waste during this process, one of the first steps is exploring eco-friendly glue options. Traditional glues often involve harmful chemicals, but innovative manufacturers are creating adhesives with reduced environmental impact while maintaining the superior mechanical properties required for beam lamination.

Comparing glued vs. unglued lumber beams, it’s evident that gluing enhances the structural integrity and dimensional stability of the final product. Moreover, exploring different types of glues allows contractors to choose options with varied curing times and temperatures, catering to diverse construction needs. You can find us at 18 Clifton St, Unadilla, NY 13849, where we stay at the forefront of these innovative construction methods using glue laminated beams while ensuring sustainability without compromising quality.

Adopting Automated Systems for Reduced Waste

Adopting automated systems for beam gluing can significantly reduce waste and enhance efficiency in construction projects. These advanced machines are designed to apply glue precisely, ensuring optimal contact between the lamina and minimizing excess material. By implementing automated systems, builders can streamline the process of How Glue Laminated Beams are Made, adhering to best practices for field assembly of glue laminated beams while eliminating manual inaccuracies that lead to waste.

Advances in wood adhesive bonding technology play a pivotal role in this transformation. Newer glues offer improved bond strength and flexibility, enabling more precise application techniques for optimal strength. This, coupled with automated systems, ensures that each beam is glued efficiently, reducing material wastage. For example, visiting unalam.com can provide insights into the latest innovations in this field, offering a glimpse into how these technologies are revolutionizing the construction industry.

Reducing waste during beam gluing is not only an environmentally conscious choice but also a strategic move for the construction industry. By understanding the processes, identifying waste generation points, and implementing efficient techniques, manufacturers can significantly cut down on material wastage. Optimizing cutoffs, exploring eco-friendly glues, and adopting automated systems are game-changers in this endeavor. With these strategies, the industry can create more sustainable How Glue Laminated Beams are Made while ensuring a robust and efficient production process.